Unfortunately, I tore my calf muscle about a week & a half ago skiing in Utah, which has really

put a damper on rocket building and pretty much everything else. Worse, I have taken a lot of my OLD rockets out of storage few weeks ago (a Brutus, Maximum Thrust Thunderbird, and a few other 15+ year old HPR rockets) to show my kids, and clean up for flying this weekend at Bong. Given how thick the snow is, I can’t imaging wading through it all in my leg cast trying to recover the rockets

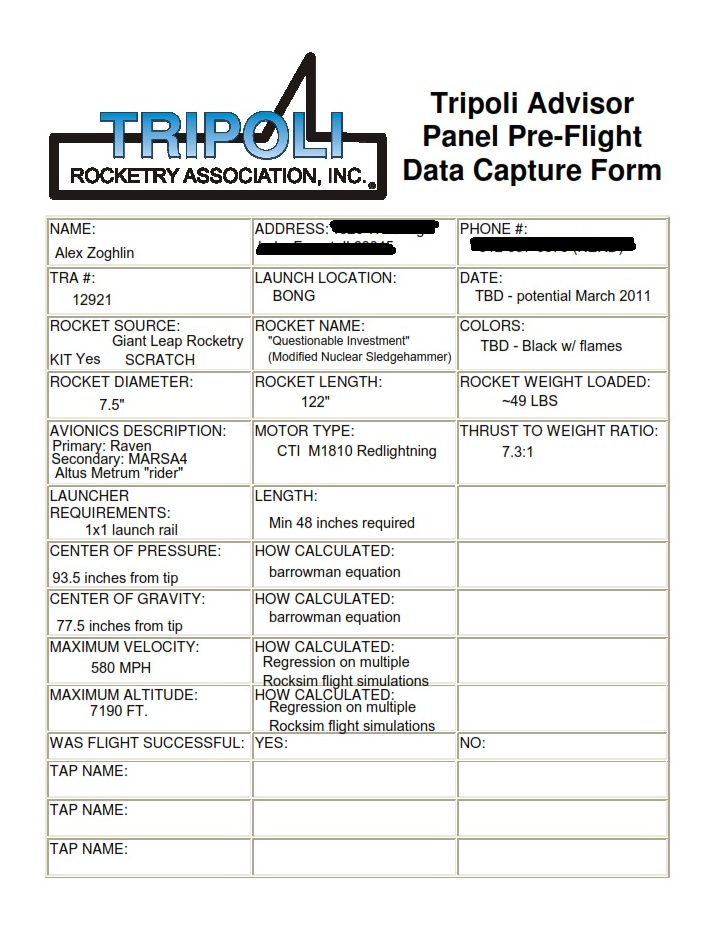

. I’ll still go up to see if either of my tap sponsors want to see my progress, but if I fly something, it will be small.

I was able

to get the wings on. First, I had to re-cut the wing slots. The lower portion was glassed over when I made the fin-can, and the whole slot itself wasn’t quite thick enough for the wings to fit through. I repeated the process on the other side, until I could dry fit both wings with a tight fit. One of the issues I will have with the wings is my limited ability to make interior fillets since both sides of the centering rings are already glued in place. First, I filled the interior of the wing’s nomex honeycomb with epoxy and put it into the slot. I let the epoxy ooze out of the honeycomb, then removed the fin. This gave me a line of epoxy on the motor tube where the wing made contact. I repeated that process a few times to build up the epoxy on the motor tube. I then drilled a few half-holes in the wing-slots which allowed me insert a syringe into the body and add epoxy for a sloppy, but effective internal fillet on each side of the wing. Once it was dry, I was able to look through the upper center ring hole I made to pour foam to ensure a the wing was touching, and had a a fillet, and taped it up to cure. I repeated the same process on the other side until both wings were secure w

ith internal fillets.

I used the same epoxy and process for the wings, that I used on the fins. Measure and mark the fins and sustainer, lay down tape across the markings, and fill in the middle with epoxy. The process

was a little more tricky than the fins because the wing is more than twice the length. Worse, there was not enough clearance between the wing

and the fin for me to use the same diameter washer I had used on the fins. Eventually, I settled on using my finger to spread, and create the fillet, dipping it in alcohol between pulls, exactly like using the washer. The result was significantly more messy,

but just as effective in creating a very smooth fillet, with clean lines. This will reduce the amount of sanding I will have to do before glassing the fins.

Once everything was dry, I separated the booster from the upper

sustainer which I was using as a lever to keep the lower sustainer in my rocket holder to mount the sustainer upright. It’s foam time! Once again I calculated the empty volume on each wing side, mixed the proper amount (266 ML, half part A, half part B), made a quick funnel out of paper and poured in the foam. Within about 5 minutes, the foam had expanded, almost perfectly to the bottom of the pour hole. I love it when a plan actually works so well! I repeated the same process on the other side, mixing exactly the same amount of foam, but when it was done expanding, I could barely see to top through the pour hole.

Yikes! Luckily, my kids weren’t around to see the utter failure of math and science’s ability to predict an outcome. II now had no idea how much volume was left in the sustainer, so I had to do the one thing I hate to do…. guess. As you can imagine, I didn’t guess right, and you can see the results on the right – an oozing mess out of the top of the second pour

hole. Luckily, this is not as bad as it looks, and I have a fair amount of experience digging foam out of tight spots thanks to a lot of lawn darts during my magnetic ejection trials. five minutes with my trusty foam extractor (a special grapefruit knife), and a little sanding, and it almost looks like I got it right the first time. I’m now going to move everything out of my office and into my garage in preparation for the massive amount of sanding I’m going to need to do. I would like to thank an anonymous reader for the tip on where to find sanding discs for my 3d sander. A kit of 100 can be had at a retailer named Micro-Mark

here. Of course, there are lots of other goodies to be found at Micro-Mark… My package arrived the other day filled with lots of tools I didn’t know I needed until I saw them in the catalog

![]()

I ended up with on the wing tops and fin can. Worse, I can’t really fit an electrical sander in that area, so I’ve had to create all sorts of sanding devices to get into that area. You can see what looks like multiple colors on the wings and fins in the picture on the left. This is indicates in some areas I have sanded through the top layer of fiberglass into the Kevlar. That’s not necessarily a good thing,

I ended up with on the wing tops and fin can. Worse, I can’t really fit an electrical sander in that area, so I’ve had to create all sorts of sanding devices to get into that area. You can see what looks like multiple colors on the wings and fins in the picture on the left. This is indicates in some areas I have sanded through the top layer of fiberglass into the Kevlar. That’s not necessarily a good thing,

put a damper on rocket building and pretty much everything else. Worse, I have taken a lot of my OLD rockets out of storage few weeks ago (a Brutus, Maximum Thrust Thunderbird, and a few other 15+ year old HPR rockets) to show my kids, and clean up for flying this weekend at Bong. Given how thick the snow is, I can’t imaging wading through it all in my leg cast trying to recover the rockets

put a damper on rocket building and pretty much everything else. Worse, I have taken a lot of my OLD rockets out of storage few weeks ago (a Brutus, Maximum Thrust Thunderbird, and a few other 15+ year old HPR rockets) to show my kids, and clean up for flying this weekend at Bong. Given how thick the snow is, I can’t imaging wading through it all in my leg cast trying to recover the rockets  to get the wings on. First, I had to re-cut the wing slots. The lower portion was glassed over when I made the fin-can, and the whole slot itself wasn’t quite thick enough for the wings to fit through. I repeated the process on the other side, until I could dry fit both wings with a tight fit. One of the issues I will have with the wings is my limited ability to make interior fillets since both sides of the centering rings are already glued in place. First, I filled the interior of the wing’s nomex honeycomb with epoxy and put it into the slot. I let the epoxy ooze out of the honeycomb, then removed the fin. This gave me a line of epoxy on the motor tube where the wing made contact. I repeated that process a few times to build up the epoxy on the motor tube. I then drilled a few half-holes in the wing-slots which allowed me insert a syringe into the body and add epoxy for a sloppy, but effective internal fillet on each side of the wing. Once it was dry, I was able to look through the upper center ring hole I made to pour foam to ensure a the wing was touching, and had a a fillet, and taped it up to cure. I repeated the same process on the other side until both wings were secure w

to get the wings on. First, I had to re-cut the wing slots. The lower portion was glassed over when I made the fin-can, and the whole slot itself wasn’t quite thick enough for the wings to fit through. I repeated the process on the other side, until I could dry fit both wings with a tight fit. One of the issues I will have with the wings is my limited ability to make interior fillets since both sides of the centering rings are already glued in place. First, I filled the interior of the wing’s nomex honeycomb with epoxy and put it into the slot. I let the epoxy ooze out of the honeycomb, then removed the fin. This gave me a line of epoxy on the motor tube where the wing made contact. I repeated that process a few times to build up the epoxy on the motor tube. I then drilled a few half-holes in the wing-slots which allowed me insert a syringe into the body and add epoxy for a sloppy, but effective internal fillet on each side of the wing. Once it was dry, I was able to look through the upper center ring hole I made to pour foam to ensure a the wing was touching, and had a a fillet, and taped it up to cure. I repeated the same process on the other side until both wings were secure w ith internal fillets.

ith internal fillets. was a little more tricky than the fins because the wing is more than twice the length. Worse, there was not enough clearance between the wing

was a little more tricky than the fins because the wing is more than twice the length. Worse, there was not enough clearance between the wing  and the fin for me to use the same diameter washer I had used on the fins. Eventually, I settled on using my finger to spread, and create the fillet, dipping it in alcohol between pulls, exactly like using the washer. The result was significantly more messy,

and the fin for me to use the same diameter washer I had used on the fins. Eventually, I settled on using my finger to spread, and create the fillet, dipping it in alcohol between pulls, exactly like using the washer. The result was significantly more messy, but just as effective in creating a very smooth fillet, with clean lines. This will reduce the amount of sanding I will have to do before glassing the fins.

but just as effective in creating a very smooth fillet, with clean lines. This will reduce the amount of sanding I will have to do before glassing the fins. sustainer which I was using as a lever to keep the lower sustainer in my rocket holder to mount the sustainer upright. It’s foam time! Once again I calculated the empty volume on each wing side, mixed the proper amount (266 ML, half part A, half part B), made a quick funnel out of paper and poured in the foam. Within about 5 minutes, the foam had expanded, almost perfectly to the bottom of the pour hole. I love it when a plan actually works so well! I repeated the same process on the other side, mixing exactly the same amount of foam, but when it was done expanding, I could barely see to top through the pour hole.

sustainer which I was using as a lever to keep the lower sustainer in my rocket holder to mount the sustainer upright. It’s foam time! Once again I calculated the empty volume on each wing side, mixed the proper amount (266 ML, half part A, half part B), made a quick funnel out of paper and poured in the foam. Within about 5 minutes, the foam had expanded, almost perfectly to the bottom of the pour hole. I love it when a plan actually works so well! I repeated the same process on the other side, mixing exactly the same amount of foam, but when it was done expanding, I could barely see to top through the pour hole.  Yikes! Luckily, my kids weren’t around to see the utter failure of math and science’s ability to predict an outcome. II now had no idea how much volume was left in the sustainer, so I had to do the one thing I hate to do…. guess. As you can imagine, I didn’t guess right, and you can see the results on the right – an oozing mess out of the top of the second pour

Yikes! Luckily, my kids weren’t around to see the utter failure of math and science’s ability to predict an outcome. II now had no idea how much volume was left in the sustainer, so I had to do the one thing I hate to do…. guess. As you can imagine, I didn’t guess right, and you can see the results on the right – an oozing mess out of the top of the second pour hole. Luckily, this is not as bad as it looks, and I have a fair amount of experience digging foam out of tight spots thanks to a lot of lawn darts during my magnetic ejection trials. five minutes with my trusty foam extractor (a special grapefruit knife), and a little sanding, and it almost looks like I got it right the first time. I’m now going to move everything out of my office and into my garage in preparation for the massive amount of sanding I’m going to need to do. I would like to thank an anonymous reader for the tip on where to find sanding discs for my 3d sander. A kit of 100 can be had at a retailer named Micro-Mark

hole. Luckily, this is not as bad as it looks, and I have a fair amount of experience digging foam out of tight spots thanks to a lot of lawn darts during my magnetic ejection trials. five minutes with my trusty foam extractor (a special grapefruit knife), and a little sanding, and it almost looks like I got it right the first time. I’m now going to move everything out of my office and into my garage in preparation for the massive amount of sanding I’m going to need to do. I would like to thank an anonymous reader for the tip on where to find sanding discs for my 3d sander. A kit of 100 can be had at a retailer named Micro-Mark  Spent much of the day cleaning up from the snowstorm. My four kids were school free yesterday, so I spent the day shoveling, and playing in the snow with them. I did find a little time for the rocket. The picture on the left is the original plastic nosecone. The one on the right is it’s

Spent much of the day cleaning up from the snowstorm. My four kids were school free yesterday, so I spent the day shoveling, and playing in the snow with them. I did find a little time for the rocket. The picture on the left is the original plastic nosecone. The one on the right is it’s  this in my office. You would be surprised at the amount of fiberglass dust even a small sanding can create. For sanding curved surfaces, I use a Crasftman 3D sander. The sander has three floating heads each with their own circular sanding pad. This lets the sander conform to most curved surfaces, reducing the possibility of creating a slat spot using a traditional sander. Unfortunately, they don’t seem to make these anymore, so the pads are becoming a little hard to find. This is an indispensable tool for me, so if someone knows of a reasonable alternative, let me know!

this in my office. You would be surprised at the amount of fiberglass dust even a small sanding can create. For sanding curved surfaces, I use a Crasftman 3D sander. The sander has three floating heads each with their own circular sanding pad. This lets the sander conform to most curved surfaces, reducing the possibility of creating a slat spot using a traditional sander. Unfortunately, they don’t seem to make these anymore, so the pads are becoming a little hard to find. This is an indispensable tool for me, so if someone knows of a reasonable alternative, let me know!